Proven Track Record

Over the past 15 years, we have designed, built, tested, operated, and validated the world’s most advanced uranium enrichment centrifuges to meet both commercial and U.S. national security requirements. These machines operate at extreme conditions, requiring the tightest tolerances and utilizing a variety of complex materials and innovative manufacturing techniques. We can put these world-class engineering and precision manufacturing capabilities to work on behalf of customers in the energy, defense, aerospace, and chemical industries.

Centrus also has decades of experience in the production and management of uranium-based nuclear fuels at various assay levels and in various forms. Our expertise includes uranium chemistry, nuclear facility licensing, criticality analysis, and alternative uranium fuel cycles.

Product Development, Design & Advanced Manufacturing

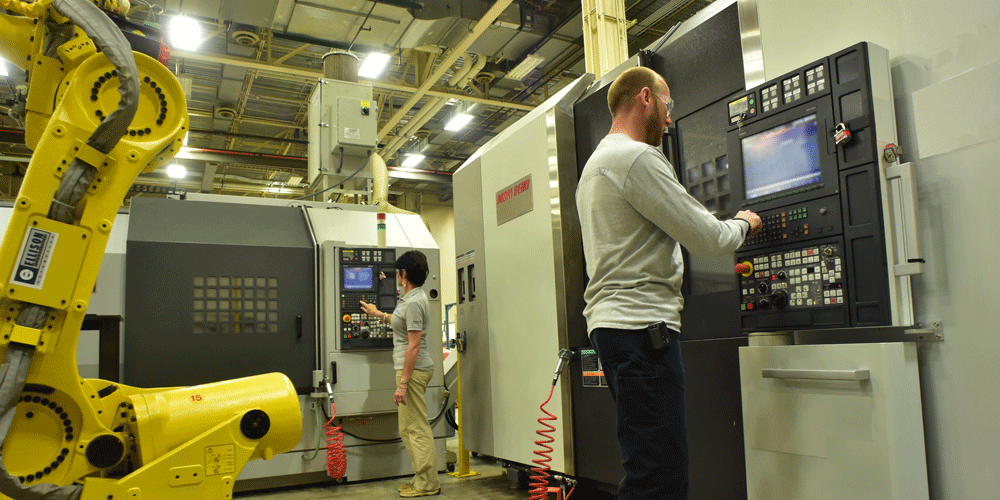

At our 440,000 square foot, state-of-the-art Technology & Manufacturing Center in Oak Ridge, Tennessee, our team of scientists and engineers transform innovative ideas into proven designs and high-quality products and components. We can produce complex components, large or small, whether you need one piece or thousands.

From design and engineering to precision manufacturing, Centrus Technical Solutions is your trusted, full-service partner.

Advanced Manufacturing

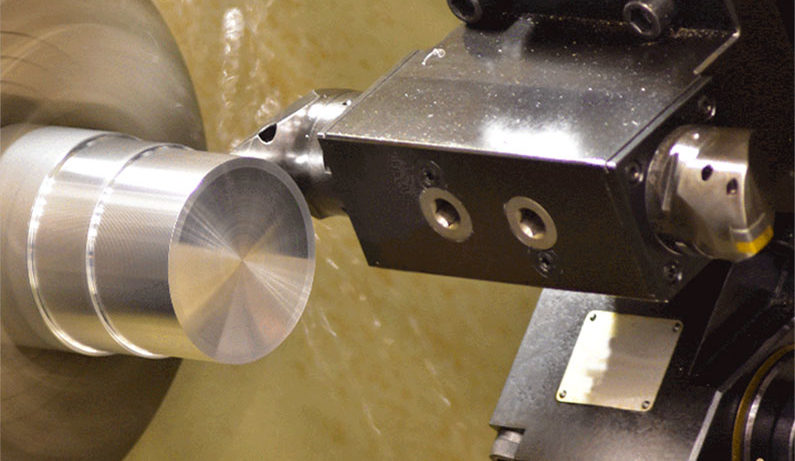

Centrus has a NQA-1 compliant, high-precision manufacturing facility. Our skilled and security-cleared workforce and supply chain partners can manufacture and assemble complex components to tolerances less than .0001 inch.

Services and capabilities include:

- Sustained volume production at ultra-high precision and very high yields at our 440,000 square ft. climate controlled, manufacturing facility.

- Production runs from a few units to thousands can be accommodated.

- Fabrication and assembly of a wide range of items can be accomplished efficiently: composite structures, metal details, motors and motor components, sensors.

- The ability to work with almost any metal or composite material, including additively manufactured structures, nuclear-grade stainless steel, nickel and many others.

- Ultra-high precision composites fabrication for parts exposed to stresses and adverse conditions, with on-site testing of completed material properties.

- Robust engineering and project management functions with a full suite of software platforms to support government and other projects.

- A security-cleared workforce and a facility approved to stringent federal security protocols for high-security projects.

Engineering Specialties

- Gas Dynamics and Gas Flow (Compressible, Rarefied, High Mach Number)

- Analysis: Thermal, Stress, Vibration, Component Failure

- Materials Science + Composite Matrices

- Vacuum Technology

- Very High-Speed Data Acquisition and Data Analysis

- Magnetic Fields

- Analog & Digital Design

- Board Design

- Software Engineering

- EMI, Grounding & Shielding

Rapid Prototyping & Testing

Our engineering and design capabilities are coupled with rapid prototyping and 3D printing to provide quick engineered solutions. With sophisticated instrumentation and control systems, we can perform detailed testing to minimize design iterations, reducing cycle times and cost. Our on-site production capability also allows you to quickly implement design revisions to your prototype, accelerating the development process.

Engineering, Design & Multiphysics Modeling

Turning innovative concepts into practical designs requires in-depth engineering and modeling. Centrus performs structural, thermal, and fluid modeling for both steady state and transient conditions. Our analysis services include finite element analysis as well as magnetic and vibration modeling for defense, aerospace, and nuclear applications.

Small Business Contractor

Centrus is considered a small business for many categories of contract work under the North American Industry Classification System (NAICS).

American Centrifuge Operating, LLC d/b/a Centrus Technical Solutions